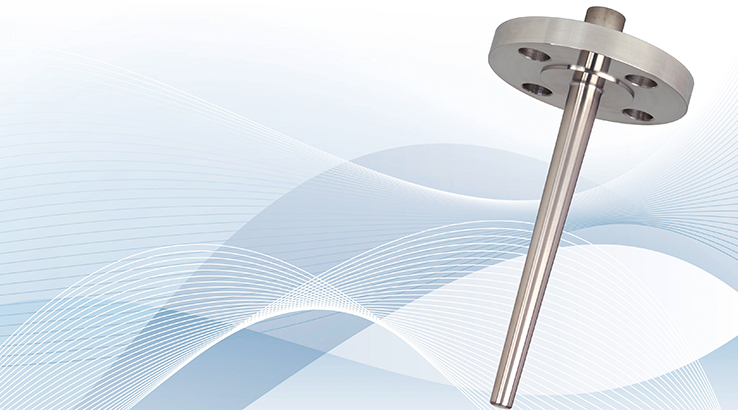

Thermowell to petrochemical standards

Vanstone design, for lap flanges in accordance with ASME B16.5

Applications

- Petrochemical industry

- For high process loads

Special features

- Exceptionally heavy-duty design in typical Shell design

- Solid-machined version without welding

- Manufactured in accordance with Shell specifications

- S38.113 and S38.114, all revision levels

- MESC 76/033 (February 2014) - if specified - For loose flanges per ASME B16.5

Description

Each thermowell is an important component of any temperature measuring point. It is used to separate the process from the surrounding area, thus protecting the environment and operating personnel and keeps aggressive media, high pressures and flow rates from the temperature sensor itself and thereby enables the thermometer to be exchanged during operation.

Based on the almost limitless application possibilities, there are a large number of variants, such as thermowell designs or materials. The type of process connection and the basic method of manufacture are important design differentiation criteria. A basic differentiation can be made between threaded and weld-in thermowells, and those with flange connections.

Furthermore, one can differentiate between fabricated and solid-machined thermowells. Fabricated thermowells are constructed from a tube, that is closed at the tip by a welded solid tip. Solid-machined thermowells are manufactured from bar stock or from forged blanks.

The TW31 series of solid-machined thermowells for lap flanges are suitable for use with numerous electrical and mechanical thermometers from WIKA.

Due to the exceptionally heavy-duty design, these international-design thermowells are the first choice for use in the petrochemical and chemical industries and in plant construction.